Fused Quartz Crucible

click:175

belong to:Fused Quartz Crucible

Release time:2025-03-14 08:30:41

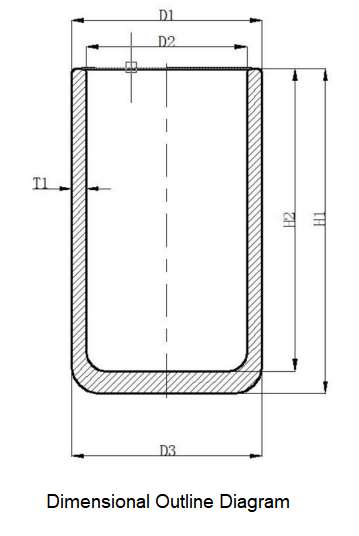

Size Specifications

· D1 - Upper Outer Diameter

· D2 - Upper Inner Diameter

· D3 - Lower Outer Diameter

· H1 - Outer Height

· H2 - Inner Height

· T1 - Wall Thickness

· R - Fillet

|

Item |

Alloy Melt Capacity |

Size Specifications |

||||||

|

D1(mm) |

D2(mm) |

D3(mm) |

H1(mm) |

H2(mm) |

T1(mm) |

R(mm) |

||

|

EC-10 |

10kg |

130 (±1) |

102 (±1) |

124 (-1, 0) |

218 (0, +2) |

206 (0, +2) |

10 (±1) |

3~5 |

|

EC-12 |

12kg |

130 (-1, 0) |

102 (±1) |

126 (-1, 0) |

244 (±1) |

227 (-1, 0) |

14 (±1) |

3~5 |

|

EC-15A |

15kg |

127 (±1) |

109 (±1) |

119 (-1, 0) |

261 (0, +2.5) |

248 (0, +2.5) |

10 (±1) |

3~5 |

|

EC-15B |

15kg |

146 (±1) |

126 (±1) |

134 (-1, 0) |

242 (0, +2.5) |

229 (0, +2.5) |

10 (±1) |

3~5 |

|

EC-25 |

25kg |

162 (±1.5) |

143 (±1.5) |

150 (-1.5, 0) |

310 (0, +3) |

297 (0, +3) |

10 (±1) |

3~5 |

|

EC-35 |

35kg |

175 (±2) |

157 (±1.5) |

163 (-1.5, 0) |

302.5 (0, +3) |

288 (0, +3) |

9 (±1) |

3~5 |

|

EC-50 |

50kg |

207.5 (±2) |

183 (±2) |

195 (-2, 0) |

304 (0, +3) |

290.5 (0, +3) |

12.5 (±1) |

≥5 |

|

EC-90 |

90kg |

257 (±2.57) |

221 (±2.21) |

246 (±2.46) |

436 (±4.36) |

416 (±4.16) |

18 (±0.9) |

≥5 |

|

EC-120 |

120kg |

282.9 (±2.82) |

247.8 (±2.47) |

271.7 (±2.71) |

430 (±4.3) |

409.7 (±4.09) |

17.5 (±0.9) |

≥5 |

|

|

The crucible is not allowed to have sharp edges, right angles, and the inner fillet of the upper end is ≥8mm |

|||||||

Physical and chemical index

Chemical Composition:

|

Al2O3 |

SiO2 |

TiO2 |

Fe2O3 |

MgO |

K2O |

Na2O |

|

% |

% |

% |

% |

% |

% |

% |

|

60-70 |

30-40 |

≤ 0.22 |

≤ 0.20 |

≤ 0.14 |

≤ 0.08 |

≤ 0.23 |

Impurity Elements:

|

Pb |

Bi |

Ag |

Sb |

Zn |

Sn |

|

Wt% |

Wt% |

Wt% |

Wt% |

Wt% |

Wt% |

|

<0.0025 |

<0.0001 |

<0.004 |

<0.004 |

<0.0075 |

<0.004 |

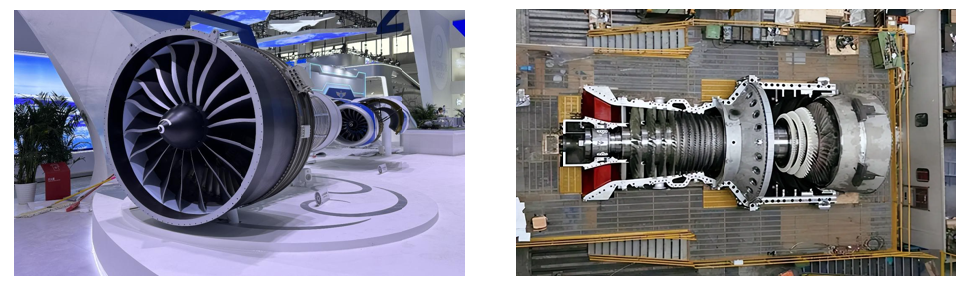

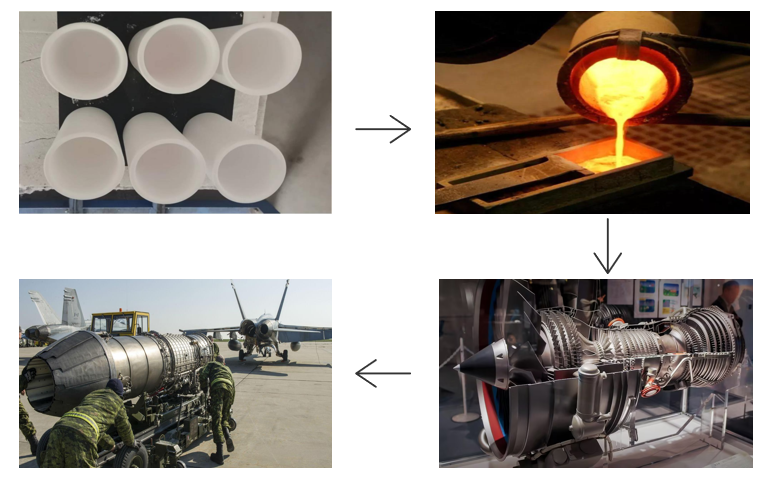

Product Usage Examples

Aerospace & Marine Turbine Blades

Fused quartz crucibles are used in the precision casting of single-crystal turbine blades for aircraft engines and marine gas turbines, ensuring high strength, thermal shock resistance, and minimal contamination.

Single-Crystal Alloy Casting

Essential for melting and casting single-crystal superalloys, providing superior thermal stability and purity to meet the stringent requirements of high-temperature applications.

Semiconductor & Photovoltaic Industry

Used in the production of high-purity silicon ingots for semiconductors and solar panels, ensuring minimal impurities and excellent thermal resistance.

Advanced Ceramics & Specialty Glass

Supports the synthesis of high-performance ceramic materials and specialty glass manufacturing processes that require extreme thermal stability and chemical purity.

- prev:null

- next:null

0086-15037978556

0086-15037978556

EMAIL

EMAIL WHATAPP

WHATAPP TOP

TOP